FAQ: Psychrometric Charts in Cold Storage Humidity Control

Summary

What is the main threat to cold storage facilities according to Eldridge?

The main threat isn’t the cold temperature itself, but moisture and humidity, which Eldridge describes as ’the silent saboteur’ that undermines safety, efficiency, and profitability in temperature-controlled facilities.

Why is humidity particularly problematic in cold storage environments?

Humidity creates three major problems: coil frosting that insulates cooling coils and reduces efficiency, icing and fogging hazards that create safety risks for workers and equipment, and energy waste from frequent defrost cycles and latent heat removal.

How do psychrometric charts help solve humidity problems in cold storage?

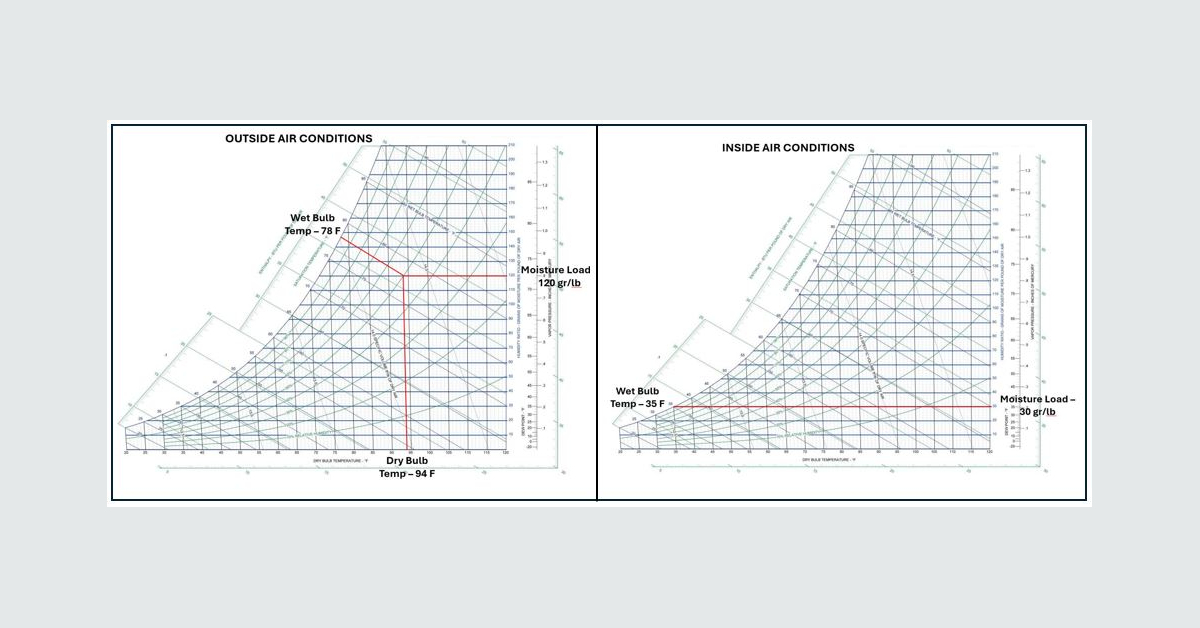

Psychrometric charts allow engineers to model air’s thermodynamic properties by plotting dry-bulb, wet-bulb, and dew point temperatures, enabling them to visualize when and where condensation or frost will form and design systems that keep air safely below its dew point.

What specific benefits does using psychrometric charts provide for cold storage facilities?

Using psychrometric charts enables proactive safety management by identifying high-risk zones in advance, reduces maintenance cycles, protects workers before hazards occur, and improves energy efficiency by preventing frost formation and optimizing system sizing.

Can you provide an example of how Eldridge used psychrometric analysis in practice?

In one case study, Eldridge modeled outside air at 94°F dry-bulb/78°F wet-bulb against a 35°F cold storage environment, revealing a 90-grains-per-pound moisture differential that guided precise sizing of desiccant dehumidifiers to prevent frost formation.

What temperature range do cold storage facilities typically operate within?

Cold storage facilities typically operate between 0°F and 40°F, but these low temperatures amplify humidity problems rather than creating them.

Who is Eldridge and what expertise do they bring to this field?

Eldridge is a Houston-based company established in 1946 that specializes in industrial ventilation and dehumidification solutions, providing technical applications in ventilation, noise control, air filtration, and process cooling/heating across various industrial sectors.

What key measurement determines success in cold storage design according to Eldridge?

The dew point, not just the thermometer reading, determines success in cold storage design because it indicates when and where condensation or frost will form.

How does this approach change cold storage management practices?

This approach shifts cold storage management from reacting to problems after they occur to preventing them entirely through smarter engineering that anticipates and controls humidity behavior in advance.

This story is based on an article that was registered on the blockchain. The original source content used for this article is located at Newsworthy.ai

Article Control ID: 251500